- Project title: Lightweight solutions for e-mobility by AM of soft magnetic alloys

- Project acronym: SOMA

- Start date: January 1st, 2021

- Duration: 36 months

- Area: D2 Acceleration

- Segment: D2.2 Upscaling project

- Lighthouse: Sustainable Materials for Future Mobility

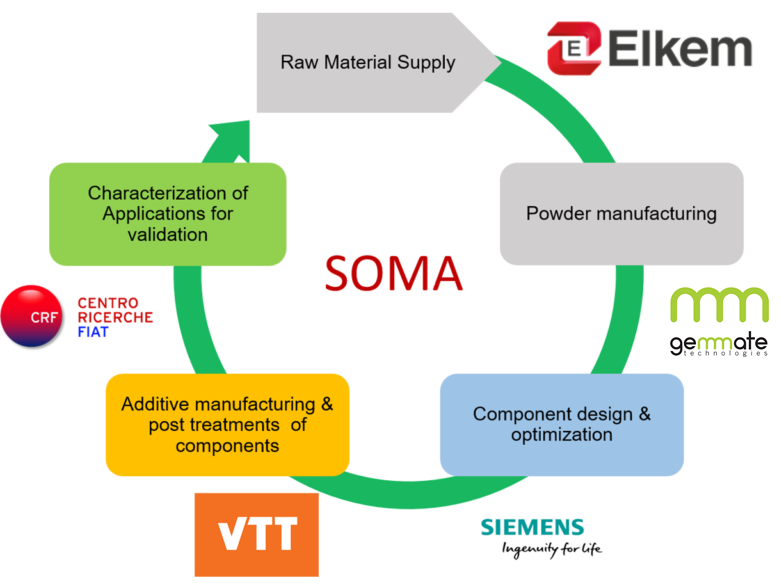

The SOMA project, supported by EIT Raw Materials, is answering to electric mobility (e-mobility) demand for more optimized electromechanical devices with enhanced performance, lower material consumption and life cycle cost. This demand is pushing the manufacturers and research community to explore unconventional designs and manufacturing methods. Additive manufacturing technologies have opened up new possibilities for realizing magnetic circuit designs free from the restrictions of conventional manufacturing methods. Earlier studies have shown that by tailoring material compositions together with optimized processing parameters and post-treatments, high performance soft magnetic components can be manufactured by laser powder-bed fusion (L-PBF). Further, it has been shown that through topology optimization, the weight of an electrical machine can be decreased significantly without compromising the other key characteristics. The SOMA project is focused on the upscaling of soft magnetic alloys tailored for additive manufacturing with minimized amount of critical raw materials. Further, SOMA will demonstrate a manufacturing route where the design is not limited by the restrictions of conventional manufacturing methods enabling groundbreaking changes in design and hence leading to higher energy densities and higher performance connected to lightweight, material efficient constructions for future e-mobility.

The consortium combines powder and electromagnetic experts. The re-desinged products manufactured with SOMA soft magnetic alloys are domonstrated in an operational environment by CRF and Siemens, while the powder commercialization is led by Elkem. Gemmate’s role concerns the designing of topology optimized lightweight components for the assembling of a topology optimised electrical machine and its integration with the vehicle underbody.